A stripped screw head, sometimes called chewed screw head, are the result of improper or careless use, which has caused some damage to the heads of your screws. Whether you’re a motorcyclist, a DIY’er, or a skilled trades person, a stripped screw head can turn a 5 minute job into a 35 minute job. And that’s only if you’re lucky. So how do you get out a screw with a stripped head? Well, there are a number of known ways, but today I discovered a new one.

Today’s post is going to look at how to extract a screw with a stripped head. We’ll cover tried-and-true ways and a new way I just learned about. These work whether you’re dealing with an Allen (hex) head, Philips (cross) head, Torx (star) head, square (diamond) head, or anything else. I’ll share some pictures and a video along the way for the visual learners.

Removing a Screw With a Stripped Head – Tried-and-true Methods:

Method #1: Extracting a screw with a hammer

Method #1: Extracting a screw with a hammer

Since the time of the caveman, mankind has discovered one tried-and-true solution for fixing issues. Whatever your problem is, hit it really hard with something. In this case, the idea is to hit the stripped screw head with the proper sized screw driver or drill bit using a hammer. You want to hit it so hard that it sinks into the screw head a little more, giving you some fresh surface to use for leverage.

Believe it or not, the caveman gets a point for this one. I’ve tried it. It works. But, hitting something with a hammer isn’t always a good thing. Especially on a motorcycle. Depending on what this stripped bolt or screw is going into, and how strong the metal and other components around it are, hitting a screw like this could be a terrible idea.

Method #2: Removing a stripped screw with a rubber band

Method #2: Removing a stripped screw with a rubber band

Congratulations! You finally have a reason to have kept those random rubber bands in that drawer full of other random stuff. Another solution people like is to use a rubber band between the stripped bolt and whatever screw driver or bit you’re trying to use. The rubber is supposed to help fill the loose space and allow your tool to regain some much needed traction.

In all honesty though, I’ve tried this on an early ’90s Honda motorcycle that a friend brought over to me, and it was 110% not successful. Big waste of a perfectly good rubber band. Your results may vary, so if you have a rubber band, why not try it anyway?

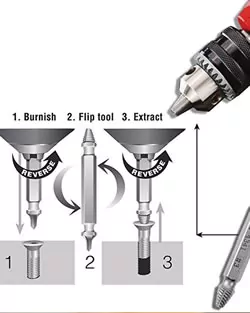

Method #3: Extracting a stripped screw with a cheap but nice screw extractor kit

Method #3: Extracting a stripped screw with a cheap but nice screw extractor kit

This is a two part method, so you should probably try the easy methods first. The idea here is we’re going to use a tool to drill a hole into center of the screw or bolt, and then use a special tool to extract the stripped head screw from the inside. Screws in screws, it’s like inception. I won’t go into detail, but this article from 2008 covers it well enough.

A good extractor kit works amazingly well. It will leave you wanting to run around the house showing your anyone and everyone who will listen to your joyous triumph. You will feel like you’re part mechanic, part God, and not at all like the knob who botched the screw head in the first place.

Considering an extractor kit costs anywhere from $10 to about $20 for a nice set that’s perfect for the average DIY’er, you’d be a fool not to keep one on hand just in case. Sooner or later you will need it, and you’ll be happy you listened to that guy from that motorcycle site on the internet. I personally just bought the $20 one.

Method #4-Inifinity: Trying absolutely everything and anything to get the screw out

Those of who don’t have a screw extractor set have all felt some serious frustration from not being able to get a screw out because of a stripped head. You’ll curse whoever thought torx heads, Philips heads or hex heads were a good idea. I get it. I’ve been that guy. It sucks. If you weren’t able to get Methods #1-3 working, you’ve probably gotten creative and tried just about anything.

Trying to get your screw to come loose with pliers or a wrench can sometimes work if you can practice extreme patience. For motorcyclists however, this can scratch whatever surface is nearest to the screw, which may not be ideal. I’ve also seen people use a small Dremel (or a $30 generic alternative) to cut a little notch in the head of a screw to try to attack it with a flat head. I’m hesitant to recommend this for motorcycle applications, because sparks and plastic and gas just seem like a terrible idea. Just use your best judgement.

In a non-motorcycle specific application, pliers, a wrench, and a dremel and a screw driver aren’t terrible options, if they work. If they don’t, you’re probably reaching peak frustration levels and are wishing you had a cheap extractor kit for a moment like this. I suggest you eat something. Peak frustration + empty tummy = how violence happens.

A new way of Removing a Screw With a Stripped Head:

Now that you have some food in you and the pulsing vein on your forehead has receded a little, let’s talk about a new way I just learned about to get screws out. It makes use of valve grinding paste, which is a really abrasive compound. This method isn’t actually new new, but it’s new to me, and maybe even you too.

The tip comes from Delboy, a.k.a. Moonfleet41 on YouTube. He put up this video, showing how he uses valve grinding paste to remove screws with stripped Allen/hex, Phillips/cross head, and Torx/diamond head screws. I recommend starting around 3:17 into the video:

The grinding paste is very gritty, so Delboy fills the head. In this case he is filling all three heads.

Once they’re filled, Delboy pushes a Phillips (cross head) screw driver into the screw head. He pushes down on the screw head hard and the coarse, semi-hard, semi-pliable paste fills in and compacts where the screw head was worn out. This, in combination with the down pressure being applied, gives Delboy enough grip to loosen the screw off.

Conclusion

When it comes to taking out a or fixing a stripped screw, there’s definitely more than one way to skin a cat. Some are cleaner and simpler than others. There’s no sense doing more work or getting dirtier than you need to.

Delboy’s gritty tip was passed down from his father decades ago, and it sounds like it’s done the family well. It seems to work on the same principle as the rubber band method, but it seems like the gritty hard-but-pliable nature of the paste makes it more effective in removing screws with rounded or stripped heads. The grit helps to bite into the metal to help your tool get your stuck and damaged screw out.

But it still seems kind of iffy. He has to apply a lot of downward pressure to get those screws out. For that reason, I still don’t think it’s a good substitute for the tried-and-true extractor set, and at $20, how could the average DIY’er not keep one on hand?

COMMENTS: What have you used to get rounded / stripped screw heads out? Did it work?

Please leave me a comment and let me know!

YouMotorcycle Motorcycle Blog – Motorcycle Lifestyle Blog, MotoVlog, Motorcycle Reviews, News, & How-Tos

YouMotorcycle Motorcycle Blog – Motorcycle Lifestyle Blog, MotoVlog, Motorcycle Reviews, News, & How-Tos

Method #1: Extracting a screw with a hammer

Method #1: Extracting a screw with a hammer Method #2: Removing a stripped screw with a rubber band

Method #2: Removing a stripped screw with a rubber band Method #3: Extracting a stripped screw with a cheap but nice screw extractor kit

Method #3: Extracting a stripped screw with a cheap but nice screw extractor kit

Sometimes tapping screw heads with the round end of a ballpein hammer gives enough shape back to phillips heads and tapping can also free the threads.

Have never used paste but I use a big punch and give the screws a few good hits right on the head then I take my impact driver bit , bit only,put it in the screw head and give it few good hits to re-seat the bit then use the complete impact driver to remove the screw. Use a big hammer and hit it hard. Has worked every time for me. If you don’t have an impact driver go buy one-you’ll never regret it!

Method A: Use a ball been hammer on the head to move some of the head back into position making the space smaller, & reforming the head. Then hammer a screwdriver / impact driver bit into the place it belongs. Then apply torque on the tool while also hitting the tool hard with the hammer . Works for me 7/10 times.

Method B: Use method A after applying a lot of heat. Be careful not to start a fire or melt anything.

Haven’t considered using heat before. Thanks for the tip!

If it has a raised head and you can get to it, I give it a squirt of WD40, wait about half a bottle of beer then clean the head with paper towel. Insert correct type of screwdriver (or impact driver if you have one) and give it a couple of persuasive clouts before using self tensioning mole grips on the outside of the damaged head, to turn it. If the damaged screw has a flush head, WD40, hallf a bottle of beer, paper towel followed by the Ball Pein Hammer method detailed by others. If it is a stripped flush-fitting Allen bolt, I use the WD40 and whilst waiting I chew up a small piece of newspaper and press the pulp into the bolt head. Then push the Allen Key into the pulp, tap with a hammer and gently apply the turning leverage in increasing amount till either the bolt cracks and turns or the Key slips out! I guess that is very similar to the Grinding Paste method! Newspaper is often easier to find than the paste though!

Chewing up newspaper eh, is that part of the rehabilitation? Glad to see you around brother!