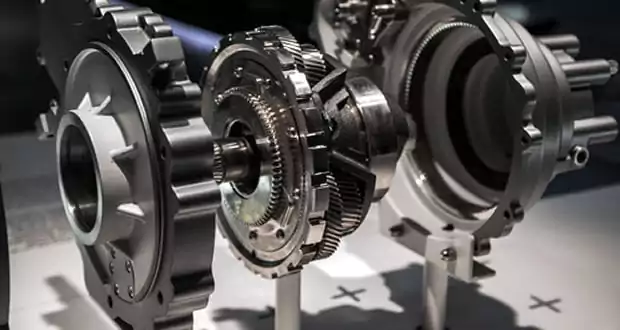

Planetary gears (commonly known as epicyclic gear train) has its own in-line shafting and cylindrical casing. It is often recognized as the light alternative to conventional pinion-and-gear reducers. Shaped to provide a wide array of applications—from electric screwdrivers, motorcycles, bulldozers, and power trains—these components are tough contenders for space and weight versus depletion and revolution which are primary concerns. To fully grasp the operation, one must study the details. Analyzing the overall construction and mechanism of planetary system has shed light to some of the less obvious factors that go along into the play.

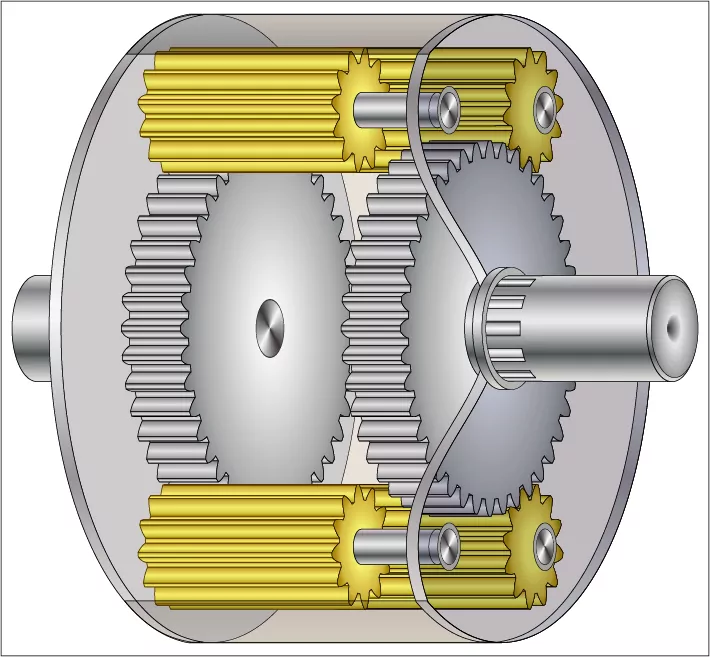

A planetary gear can be built so that the planet gear moves toward the inside of the pitch circle of a rigid, outer gear ring, or ring gear, often called an annular gear. In most cases, the curve traces by a point on the pitch circle of the planet which is named as a hypocycloid.

A planetary gear train is the combination of an epicycle gear train with a planet that engages both the sun gear and the ring gear. Often, the ring gear is usually placed intact, and the sun gear is driven.

The purest form of planetary gear that is often used in motorcyles usually covers three sets of gears with various degrees of independence. The planet gear rotates around axes that spin around the sun gear, which revolves in place. The ring gear holds the planets on the outside and is completely intact. The main concentration of the planet is with the alliance of the sun and ring gears that the torque shifts through a straight line.

Planet gears especially for motorcycles, have various sizes, they engage a lot of teeth as they spin around the sun gear – hence they can easily hold countless turns from the driver per output shaft revolution. Performing a comparable depletion between a simple pinion and gear, the sizable gear will entail to a web with the small sprocket.

The planetary gear is composed of a sun gear, planet gears, supported by the carrier and a ring gear.

The range of speeds that the motorcycles can get from planetary gears differs widely depending on the execution. The size of the gear steer largely influences the speed rating, because a higher pitch line velocity can be defined as a temperature increase far beyond any cooling effect from the larger geometry.

Planetary gear in motorcycle gives enormous power density as compared to simple parallel axis gear. It provides a depletion in volume, multiple kinematic combinations, purely torsional reactions, and coaxial shafting.

The productivity loss of a planetary gear in a motorcycle is about 3% per phase.The efficiency ensures that a high section (about 97%) of the energy being transferred through the gearbox, rather than being lost on mechanical losses inside the gearbox.

Planetary gear in a motorcycle also gives stability because of the even distribution of weight and increased rotational stiffness. Torque applies radially onto the gears of the planetary gear and is then transmitted radially by the apparatus, minus lateral pressure on the teeth of the gear.

The weight of a planetary gear is shared among multiple planets; hence, torque capability is greatly elevated. The more planets in composition, the greater the load ability and the higher the torque density.

In a typical execution, the drive power connects to the sun gear. The sun gear then drives the planetary gears built with the external gear ring to function well. The whole set of planetary gear spins on its own axis and along the outer gear ring where the output shaft connected to the planetary carrier achieves the goal of speed depletion. A higher depletion rate can be obtained by doubling the multiple staged gears and planetary gears.

The procedure of motion of a planetary gear structure is different from essential parallel gears. Traditional gears depend on a small number of contact points between two gears to transmit the driving force. In this case, all the loading is directed to a particular area on a few contacting surfaces, making the gears wear quickly and sometimes crack. On the other hand, the planetary speed reducer has various equipment contacting surfaces with a larger area that can share the burden evenly around the central axis. Multiple gear surfaces share the load, including any immediate impact loading, smoothly, which make them more capable of absorbing damage from higher torque. The housing and bearing parts are also less likely to be damaged and crack from top loading.

YouMotorcycle Motorcycle Blog – Motorcycle Lifestyle Blog, MotoVlog, Motorcycle Reviews, News, & How-Tos

YouMotorcycle Motorcycle Blog – Motorcycle Lifestyle Blog, MotoVlog, Motorcycle Reviews, News, & How-Tos